Kistler acquires SEMTEC to expand its ICE combustion analysis capability

The growing demands for zero-emission operation of combustion engines can only be met with high-performance measurement technology. To optimize engine designs, automobile manufacturers must rely on precise analyses of the combustion process. With the visual combustion analysis from SMETEC, processes in the combustion chamber can be visualized allowing the quality of the combustion process to be analysed in real time.

The new technology complements Kistler’s measurement technology, especially in the area of pressure sensors, and adds further options in combustion analysis. This technology provides engine development and research technicians with the widest combination of combustion analysis options for understanding and optimising the combustion process.

The foundation of the new optical measurement technology is a multifunction measuring spark plug combining cylinder pressure measurement and visual combustion analysis in one product. A range of support equipment includes highly sophisticated optical probes that precisely detect the origin of combustion knock, as well as the origin of pre-ignition events and even soot formation within the combustion chamber. Where needed, high-speed imaging cameras for recording fast injection events and flame propagation processes and high sensitivity light amplifiers for fibre optic applications with up to 16 light input channels may be specified. A high intensity, high-performance light source may be used as a continuous or pulsed light source to provide high light output and, in pulse mode, high repetition rate.The growing demands for zero-emission operation of combustion engines can only be met with high-performance measurement technology. To optimize engine designs, automobile manufacturers must rely on precise analyses of the combustion process. With the visual combustion analysis from SMETEC, processes in the combustion chamber can be visualized allowing the quality of the combustion process to be analysed in real time.

The new technology complements Kistler’s measurement technology, especially in the area of pressure sensors, and adds further options in combustion analysis. This technology provides engine development and research technicians with the widest combination of combustion analysis options for understanding and optimising the combustion process.

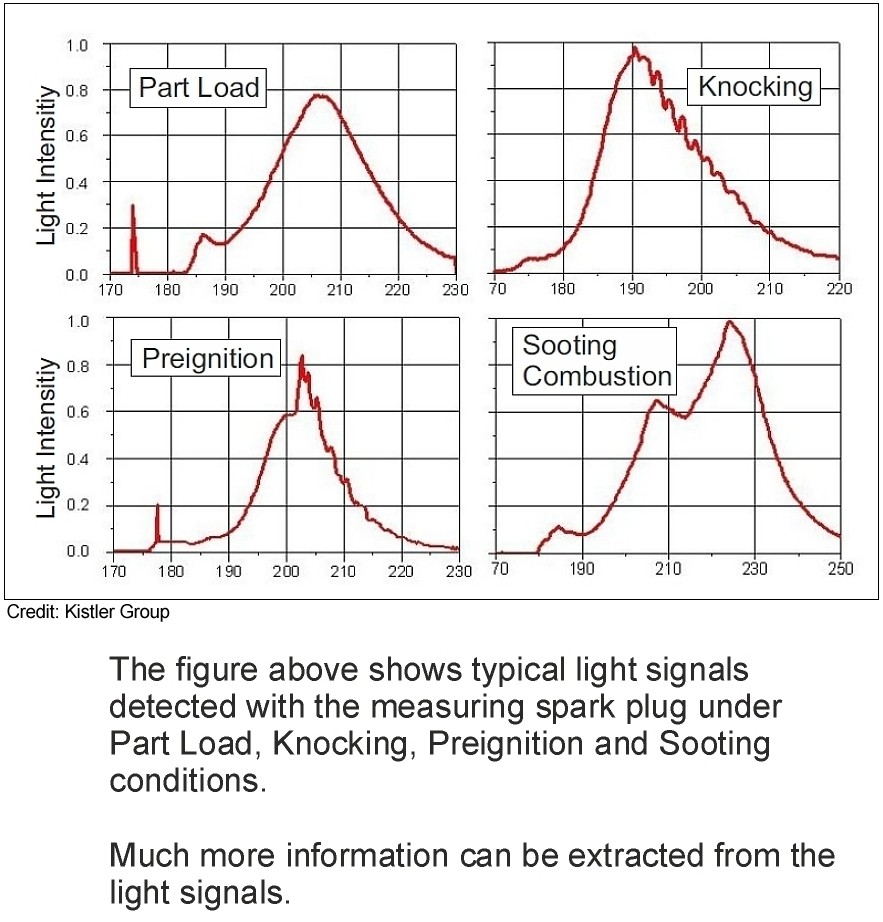

The foundation of the new optical measurement technology is a multifunction measuring spark plug combining cylinder pressure measurement and visual combustion analysis in one product. A range of support equipment includes highly sophisticated optical probes that precisely detect the origin of combustion knock, as well as the origin of pre-ignition events and even soot formation within the combustion chamber. Where needed, high-speed imaging cameras for recording fast injection events and flame propagation processes and high sensitivity light amplifiers for fibre optic applications with up to 16 light input channels may be specified. A high intensity, high-performance light source may be used as a continuous or pulsed light source to provide high light output and, in pulse mode, high repetition rate.

In addition to hardware and software, Kistler SMETEC can supply a range of engineering support services from advising users on the most effective techniques for applying optical measuring to the engine to a full on-site engineering service. Experienced combustion measurement engineers support the user from preparing the engine through advising and installing the measuring equipment to conducting the process on the test bed and on road followed by the presentation of a detailed analysis of the results. In addition, where the analysis equipment is required only for a short term project, both hardware and software may be rented so avoiding capital investment.